1. Surface Preparation

Powdercoating NZ preparation processes include sandblasting, a range of thorough industry standard chemical pre-treatment processes and high quality primers and undercoats. Surface preparation must be immaculate. All items are thoroughly quality control checked before proceeding to the next part of the powdercoating process.

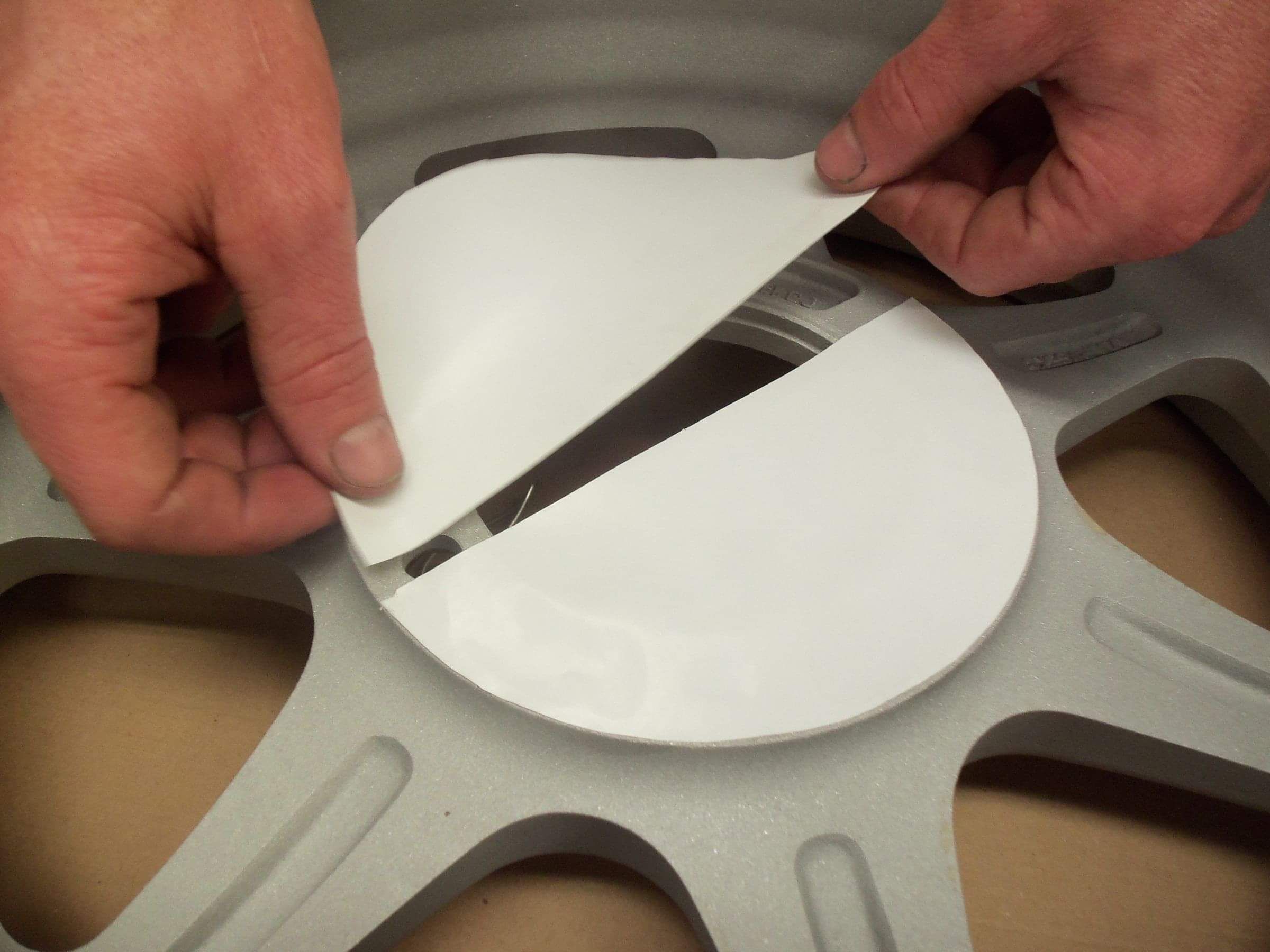

The next step is to suspend the items to be powdercoated from a trolley frame using suitable tools and techniques from our specialist and extensive range which we have developed over the years. If required, any additional dressing, masking or surface preparation is carried out at this point.

2. Powdercoating Application

The trolley of items to be powdercoated proceeds to the powdercoat application booth. Here, all other contaminants such as sand or dust is removed. The powdercoating is applied by an experienced applicator using an electrostatic powder application gun and the powder of your choice. Special care is taken to target all the acute angles and hard to reach areas which are often missed in automatic and big operations. At this point, the powdercoat is adhered to the metal via an electrostatic attraction but is still in dry powder form.

Once completed the powdercoat applicator double checks his coverage before pushing the trolley into the bake oven.

3. Curing the Powdercoating

Powdercoating bake ovens normally operate between 180°C and 240°C. Each powder applied has a specific cure schedule. This means that the powdercoated items need to be baked for a specific duration at a specific temperature in order to achieve a hardened and uniform surface finish which is aesthetically enhancing and corrosion protecting to the metal.

Once the bake cycle is complete, the trolley of items are removed from the bake oven and allowed to cool to ambient temperature.

4. Final Quality Check & Packing

Once cooled, a specialist Quality Control Assessor thoroughly checks to ensure that the items pass the stringent Powdercoating NZ quality control standards.

"Our primary focus is customer satisfaction and maintaining due care and premium quality throughout all processes. I will never present a customer with a finished product unless I'd be satisfied to have the finished product in my own home." - Chris Morris, Head of Quality Control

If required, your items will be packaged or palletised for safe transport prior to your collection.